- Author:

- Daniel Smith, Betsy Young

- Subject:

- Architecture and Design, Visual Arts, Manufacturing, Welding

- Material Type:

- Lecture Notes

- Level:

- Community College / Lower Division

- Tags:

- License:

- Creative Commons Attribution

- Language:

- English

Welding Technology Department: Architectural and Ornamental Metals

Overview

Basic skill development in hand-forging steel, forge welding, scroll-forming, shaping, and joinery utilizing hammers, anvils, and coal and gas forges. Emphasis on techniques and processes to demonstrate versatility and skill.

Metalsmithing: WLDG 1401

Link to Metalsmithing syllabus

SYLLABUS

Course Description

Basic skill development in hand-forging steel, forge welding, scroll-forming, shaping, and joinery utilizing hammers, anvils, and coal and gas forges. Emphasis on techniques and processes to demonstrate versatility and skill. Course Fee: $50.00; Course Type: W

Copy link below, or follow link above, or download file to view the whole syllabus.

https://drive.google.com/file/d/19U8882UO_SYHpm9HLjfKnVG6wXVgOOmL/view?usp=sharing

"Forging Ahead Works Progress Administration" by Herzog, Harry is in the Public Domain

Blacksmithing Skills Overview

Blacksmithing is a highly skilled occupation that makes many demands on the mind and body. While learning this extremely rewarding profession, we will be using mathematics, physics, chemistry, and history to aid us in the forging of steel. As we explore what it means to be a modern blacksmith, we will look at how the blacksmith is affected by steel choices, fuel choices and finishes applied to the steel.

ABANA is the Artist Blacksmith Association of North America. They are one of the professional blacksmithing organizations for this part of the world. There are other groups including British Artist Blacksmiths Association (BABA), Irish Artist Blacksmithing Association (IABA). There are also individual chapters in various states around the USA. Balcones Forge and Houston Area Blacksmiths Association are two that are found in Texas.

ABANA has a list of skills expected of a Journeyman blacksmith. A journeyman is a blacksmith with a basic set of skills that travels to blacksmithing shops around the country to learn from different shop owners and master blacksmiths. This practice was more popular long ago and it is more common in Europe.

SKILLS EXPECTED FOR THE EMPLOYMENT OF A JOURNEYMAN

Blacksmithing Standards developed by the Appalachian Blacksmiths Association, an ABANA Affiliate, and registered with the Bureau of Apprenticeship and Training, United States Department of Labor.

1. Drawing Out: Draw a bar to a point or dress an edge or point a tool.

2. Upsetting: Upset to at least 1-1/2 times the diameter or width of a bar on the end and in the middle.

3. Bending: Make a ring out of bar stock or flat stock; forge a square corner right angle bend in square stock.

4. Drifting: Make a drift and use it to smooth, shape or enlarge a hole.

6. Mortise and Tenon: Make an assembly from at least two separate pieces using this technique.

7. Collaring: Make an assembly from at least two separate pieces using this technique.

8. Scroll Work: Make two different types of scrolls.

9. Splitting: Split a bar with a hot cut in the middle or at the end of the bar.

10. Fullering, Grooving, Veining, Set Hammering: Show examples of each or if used as an intermediate technique, describe how and why the techniques are used.

11. Riveting: Make two assemblies from at least two separate pieces for eachassembly using hot riveting and cold riveting (pop riveting is not acceptable).

12. Forge Welding: Show at least three different techniques.

13. Arc Welding, Brazing, Soldering, Oxyacetylene Torch Welding: Show an example of each.

14. Hot Rasping, Filing: Hot rasp the torch cut end of a bar to reasonable straightness and evenness; show a workpiece which has been filed to a smooth, flat surface; describe the types, care and use of files.

15. Sinking, Raising, Metal Spinning: Make or show a hemispherical or hollow object made from flat sheetusing any one technique.

16. Grinding: Know how to use a body grinder (portable grinder), pedestal grinder, belt grinder, sharpening stones and abrasive papers; know the types of abrasives and how they are graded and classified; show an edge tool that you have sharpened.

17. Drilling, Tapping, Die Work and Threads: Drill and tap a hole, thread the end of a bar with a die; know the common thread classifications; know the common drill size classifications and the care and use of twist drills.

18. Heat Treating, Hardening, Tempering, Annealing, Case Hardening: Know how to properly anneal, harden and temper carbon tool steel; know how to case harden mild steel, know the colors for tempering; make or show a tool you have made that has been heat treated that will cut or forge mild steel without breaking or deformation on the working end.

19. Heading: Head two bolts, one square headed and one hex headed; head a nail; head a rivet.

20. Cutting and Shearing: Know how to use the hot cut, cold cut, hacksaw, tinsnips, bench or floor shear; know how to use the oxyacetylene torch for cutting and demonstrate each technique.

21. Swaging: Swage a tenon or make the end of a square bar round using a swage.

22. Twisting: Show two different twists in a square bar.

23. Shop Safety: Know first aid techniques for cuts, burns, abrasion and other shop related injuries; describe methods of hearing, sight and body protection and why they are necessary; know power tool and machinery safety including welding equipment safety.

24. Basic Metallurgy: Know the properties and use of wrought iron, mild steel, carbon and tool steels and their classifications, cast-iron, brass, copper, aluminum; know sheet and plate gauging for ferrous and non-ferrous metals.

25. Fire and Fuel: Know the constituents of good shop coal; know the different types of coal fires and fire maintenance.

26. Jigs and Dies: Make both a jig and a die for doing repetitive production work and show examples of work produced with them.

"Skills of a journeyman blacksmith" by ABANA is licensed under CC BY-NC-ND 4.0

Tools Specific to Forging

There are three things needed to do basic blacksmithing, if any one of them is missing, then forging cannot take place. Some have referred to this list as the three H's

- Heat- The steel must be heated to make it soft. Heat can be gotten from several sources. The most common are gas forges (Natural gas or Propane), solid fuel forges (Coal and charcoal), Electric forges (these use induction to heat the steel, not to be confused with kilns). Oxy-Acetylene torches or oxy-propane torches can provide heat, but can be more expensive.Oxy-acetylene torches are valuable in spot heating small areas, but take a long time to heat up larger areas.

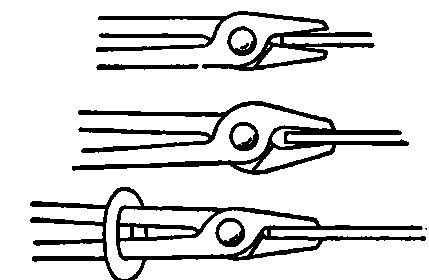

- Hold- You have to be able to hold onto the hot steel with some form of tooling. Tongs are the most common, blacksmithing specific, tools. Tongs must absolutely fit the material you are holding, otherwise blacksmithing will be frustrating and dangerous, especially with power hammer use. Steel conducts heat relatively poorly, so the bar of steel can be long enough to hold with your hand without fear of burning.

- "Tongs" is licensed under CC BY-NC 4.0

Hit- Blacksmithing uses force to shape the hot steel. The Anvil is the surface that will be hammered on, the hammer provides the striking force need to shape the metal. This is a basic list, there are other, more advanced tools, like power hammers and presses that can move the metal, but this class focuses on the hand skills.

A) Ballpeen hammer, (B) Straight peen (C+D) cross peen

"Hammers" is licensed under CC BY-NC 4.0

"Anvil" by Peter H. "Tama66" is licensed under CC BY 4.0

Forging Materials

Modern blacksmithing has many similarities with the past, but there are also many differences and many perceptions that must be changed for modern blacksmiths. There are old books describing how to take parts off of a car and forge them into tools, there are old misconceptions that you will find steel by the side of the road and you will forge it. This is highly discouraged in modern life. The steel you find is of unknown composition and it is highly likely to have a protective coating on it (NEVER HEAT METAL WITH GALVANIZING ON IT-IT PRODUCES TOXIC FUMES WHICH CAN KILL). Also what happens when you decide the fire will just burn off the paint? Now you have to breathe industrial paint fumes and often it will gum up your forge. Just buy new metal. It's safer.

Steel is highly engineered and the modern blacksmith can get exactly what they want by purchasing the steel from a dealer. You will have the benefits of knowing exactly what the steel is made of, you know it is new and undamaged, and you can spend your time forging instead of ripping apart a car. A classic example is coil springs or leaf springs from a car or truck. Yes, you can make a sword from it, but how good is that sword if it is made from a steel that spent its life being flexed 1000's of times a day until it no longer works and needs to be replaced. You spend dozens of hours getting the material, cleaning the material (in this case it is covered in paint and grease), and straightening. Finally, you can use it. I would call this mentality something like post-apocalyptic, Mad-Max thinking. Just order brand new steel, it's safer, it's better because you know exactly what you are getting (instead of guessing what Ford puts in their leaf springs) and you can get to work faster.

Here is a list of engineered metals and their designation:https://en.wikipedia.org/wiki/SAE_steel_grades

Carbon steel[edit]

Main articles: Carbon steel and Alloy steel

Carbon steels and alloy steels are designated a four-digit number, whereby the first digit indicates the main alloying element(s), the second digit indicates tg (top grade) element(s), and the last two digits indicate the amount of carbon, in hundredths of a percent (basis points) by weight. For example, a 1060 steel is a plain-carbon steel containing 0.60 wt% C.[4]

An "H" suffix can be added to any designation to denote hardenability is a major requirement. The chemical requirements are loosened but hardness values defined for various distances on a Jominy test.[3]

| SAE designation | Type |

|---|---|

| 1xxx | Carbon steels |

| 2xxx | Nickel steels |

| 3xxx | Nickel-chromium steels |

| 4xxx | Molybdenum steels |

| 5xxx | Chromium steels |

| 6xxx | Chromium-vanadium steels |

| 7xxx | Tungsten steels |

| 8xxx | Nickel-chromium-molybdenum steels |

| 9xxx | Silicon-manganese steels |

"SAE steel grades" is licensed under CC BY-SA 4.0

For example, 1018 is low carbon steel. The first two numbers indicate plain carbon steel, the second two numbers indicate the amount of carbon, .18%. Higher carbon steel would be 1080 or 1095. Remember, carbon affects the properties of the steel, more carbon (1080) can make tools (knives in this case), lower carbon, and the steel will not be able to be hardened in the heat treat.

A36 is another designation for mild steel. Mild steel is steel with lower amounts of carbon. A36 is the steel that we will be forging the most. It is hot rolled and has around .26% carbon. Mild steel is an excellent forging material, but the biggest drawback is that it will rust. The iron in the steel will combine with the environment and make iron oxide. Steel must be protected after it is forged and ready for installation. Depending on the use, this will either be painting, galvanizing, or oil/wax. Another option is to let it rust.

https://www.google.com/books/edition/Forge_practice_elementary/zoFIAAAAMAAJ?hl=en&gbpv=0

Look under pages 159-173 of John Lord Bacon's book, Elementary Forge Practice. This will give you an idea of the differences between cast iron, wrought iron, mild steel and tool steel. It is an older book found under Google books, but the information is still valuable.

"Elementary Forge Practice" by Bacon, John Lord is in the Public Domain

Laws of Physics relating to forging.

"Collisions" by EICC is licensed under CC BY 4.0

This video on collisions is especially appropriate for blacksmiths. We have an object at rest (the anvil) being acted upon by an outside force (the hammer). The weight of both the anvil and the hammer have an effect on the amount of energy transferred to the steel. The larger the anvil (250lbs is a good professional size anvil) the more inertia it has, the more it wants to stay in place. Generally, a hammer weighs around 2 1/2lbs-3lbs. Increasing the hammer weight doesn't impart as much energy as increasing the speed the hammer is swung. Raising the hammer higher above your head and striking with force will shape the metal most effectively, BUT, if you miss the metal and strike the anvil face, the force will rebound quickly returning your hammer back toward you.

!! Hammer control is huge, you will damage your arm if you swing the hammer wrong. Beginner blacksmiths should not use hammers that are too heavy. Start with a light hammer that is easily controlled and work your way up to a heavier hammer. Sledgehammers (hammers with long handles and weigh 6lbs or more) must be swung with two hands, never one-handed.

"Newton's 3 Laws" by EICC is licensed under CC BY 4.0

- As blacksmiths, we are hitting hot steel and pinching it between the anvil and the hammerhead. In THEORY, the anvil is hitting back just as hard as we are striking with the hammer. There is a loss of energy that is absorbed by the bar though. Working the material at the right temperature (usually hot) and hitting it correctly (usually hard enough to move the metal). A common mistake of beginners is they lack practice and knowing how hard to hit. Some hit too hard all the time, but most likely they hit too soft to affect the steel. Thicker stock needs heavier hammers to affect the bar all the way to the middle, too light and only the outside of the bar moves, resulting in stress cracks. Smaller diameters of steel need medium to lighter weight hammers for control. Match the hammer to the diameter.

- The Path of Least Resistance has huge implications for blacksmithing. In general, metal moves the most in thinner areas (as in forming a scroll on a tapered bar), moves more easily in the hottest area, and moves more at the end of the bar than when striking the middle of the bar. The metal is moving into open space at the end of the bar, while the blow taken in the middle of the bar has to push the steel in front of it. Identifying and controlling the path of least resistance by adjusting heat is a common way to shape steel (for example, cooling thinner areas or heating up thicker areas with a torch).

Heat Properties

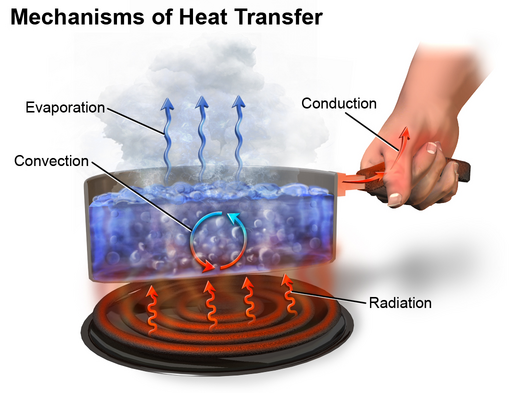

As blacksmiths we are using fire as a tool. We need to control the fire as much as possible to make the steel do as we want. We are working with temperatures ranging from 100 degrees to 2500 degrees F. We have to understand how heat travels to safely use it. REMEMBER! STEEL CAN BE AS HOT AS 1000 DEGREES F. AND SHOW NO COLOR!! Always test the steel before picking it up with bare hands.

-

BruceBlaus / CC BY-SA (https://creativecommons.org/licenses/by-sa/4.0)

- Conduction- Happens by physically touching. We are using steel tongs (Cold), we are holding steel forgings (hot). The heat in the hot steel flows into the cold tongs (hottest to coldest). Eventually the heat will travel through the steel tongs into the reins. Therefore: We must cool the tongs periodically, and we must only hold the reins of the tongs. Note: The better a piece of metal conducts electricity (like copper), the better it conducts heat.

- Radiation- Is the heat energy around something hot. When we check steel to see if it is hot, we hold our hand a few inches above it and feel for heatwaves. If nothing can be detected, the metal is lightly tapped before picking up.

- Convection- Is the circular flow of different temperatures. The hot air rises up and we can feel that above a fire.

Anvil Height

"Anvil" by Peakpx is licensed under CC BY 4.0

I chose this picture because the blacksmith is at an anvil that is the proper height. She is standing upright, has on all the protective gear and appears to have proper form. It is no longer considered correct to forge at a low anvil that causes you to bend over. Standing up straight gives you better forging dynamics. Note the smith pictured here is only wearing one glove on her tong hand, the hammer hand usually does not wear a glove because you have to squeeze through the leather and it causes more hand fatigue and blisters. Lightly control the hammer with a light grip.

The picture below shows a person at a lower anvil height, causing them to bend over. They are also wearing huge welding gloves, which make the hammer incredibly hard to control. Bending over with your back at an angle is incredibly uncomfortable. "Blacksmith at anvil" is licensed under CC BY 4.0

Steel Calculation Formulae Resources

Elementary Forge Practice, John Lord Bacon

The above book is available on Google Books as a free ebook. Its copyright expired and Google digitized it for all to see. Pages 90-95 specifically talk about using the volume of steel to calculate how much material it will take to make another shape. For example, if we start with 1" square bar, by 6" long, we can calculate how much volume is in it by multiplying length x width x height. This method works best with shapes that are common geometrics, like a cone (round taper), pyramid (square taper), cylinders, and rectangles.

"Elementary Forge Practice" by John Lord Bacon is in the Public Domain

Forge Craft Charles Philip Crowe

This is another free google book. On page 38, it describes the process of using the weight of the starting dimension of stock steel and the weight of the finished forging to determine how much stock to start with. This is especially useful if the shape is complex and not exact geometry. An example of this would be using 2" round 1045 steel to make a 3# hammerhead. How much material do you start with? First, find the weight of 2" round stock from the steel weight chart on page 58. 2" round weighs 10.68# per foot or .89# per inch. Second, Rule: Find the weight of the starting stock (2" round, 10.68) and divide by the weight of the forged article (3# hammerhead)

10.68 / 3= 3.56 inches of 2" round stock will make a 3# hammer. If I check my answer by multiplying .89# x 3.56= 3.16 pounds. Remember, we always need a little extra stock to account for loss of metal due to scaling and grinding later.

"Forge Craft, Charles Philip Crowe" is in the Public Domain

Blacksmith's Manual Illustrated, J.W. Lillico

This book is the most advanced blacksmithing book that has been cited by many of the best blacksmiths in the country as a reference source. As you become more and more skilled as a blacksmith, you will look to this book more and more. This book was written by a blacksmith for the railroad industry and has fascinating ideas on how to isolate mass using the power hammer and tooling. Page 66 (for this section) has formulae that can give you the weight of steel without a chart and advice on how to get started.

"Blacksmith's Manual Illustrated, J.W. Lillico" is in the Public Domain

Remember: In blacksmithing, it is very common to start with larger size stock and then forge it to a smaller dimension (hammering it to shape). Steel can also be upset (made shorter and fatter) as in a bolt shape. It is up to the blacksmith to decide what processes are available to them, to determine the best course of action. For example, do you have a power hammer? Do you have a torch? Some of these answers will determine your process.